|

Having earlier joined in partnership to develop the military V-22 tiltrotor, Bell Boeing revealed in February 1996 that studies were in progress for a nine-passenger civil tiltrotor aircraft in the 6,350kg weight class, with the preliminary designation D-600. Subsequently, on 18 November 1996, the two companies announced that a joint venture was being established to design, develop, certify and market a six- to nine-passenger civil tiltrotor as the Bell Boeing 609.

Boeing withdrew as a partner on 1 March 1998 and Bell subsequently teamed with Agusta to develop, produce and market the tiltrotor as the BA609; this arrangement was formally announced at the Famborough Air Show in September 1998. Agusta is investing and participating in BA609 development and will be responsible for assembly of BA609s sold in Europe and elsewhere.

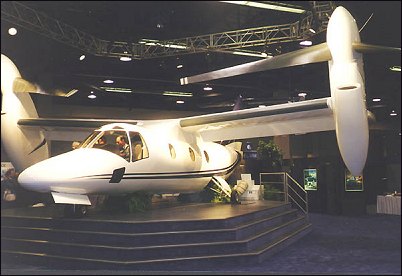

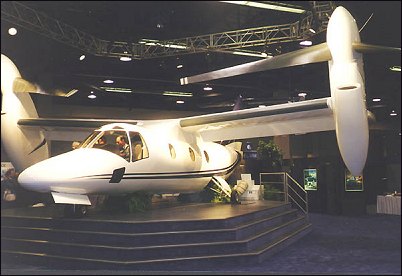

Preliminary design review completed May 1997. Manufacture of parts for prototypes began at Philadelphia, August 1997. Full-size mockup first exhibited at Paris Air Show, June 1997.

Ground-running trials began on 6 December 2002. First flight of the prototype (N609TR) took place (in the vertical mode only) on 7 March 2003, rescheduled from late 2002, following decision in April 2002 to slow development and certification as consequence of delays in Bell Boeing V-22 Osprey programme, the latter being leader in technology development. Four prototypes are being produced for 36-month flight test programme leading to certification in January 2007 under FAR Pt 25 (fixed-wing aircraft) and Pt 29 (helicopters), plus Pt 21.17(b) Special Conditions for unique components. To be capable of single-pilot IFR operation. Prototype used primarily for expansion of flight envelope, while second, third and fourth airframes are dedicated to systems certification, avionics and icing approval, and FAA function and reliability, respectively.

CURRENT VERSIONS: -

BA6O9: Initial version as described. -

HV-609: Multi-mission version proposed by Bell and Lockheed Martin to satisfy US Coast Guard 'Deepwater’ re-equipment programme as potential replacement for Dassault HU-25 Guardian, Eurocopter HH-65 Dolphin and Sikorsky HH-60J Jayhawk. Missions could include drug interdiction and SAR, with 30 to 50 HV-609s possibly being acquired. -

UV-609: Utility version conceived by Bell for US Army combat role, including casualty evacuation, command and control, logistic support and light utility/troop transport tasks. Manufacturer also promoting UV-609 to US Marine Corps as potential training system for V-22 Osprey. -

619: Projected 19-seat version aimed at commuter market; not launched by March 2003. -

620: Proposed 22-seat version conceived by Bell Boeing team; no recent news received and concept may have lapsed.

CUSTOMERS: Order book opened 2 February 1997 at Heli Expo, with first order placed soon after by unspecified customer. Total of 70 ordered by 40 customers in 18 countries by March 2003; purchasers identified to date include Helitech Pty of Australia; Lider of Brazil; Canadian Helicopter Corporation and Northern Mountain Helicopters Inc of Canada; Petroleum Tiltrotors International of Dubai; Aero-Dienst GmbH of Germany; Mitsui of Japan; United Industries of South Korea; Helikopter Services of Norway; Lloyd's Investments of Poland; Bristow of the UK; Massachusetts Mutual Life Insurance, Austin Jet and Petroleum Helicopters of the USA; and Air Center Helicopters Inc of the US Virgin Islands. Briefing given to US Coast Guard, late 1997, followed by demonstration by XV-15 tiltrotor concept demonstrator aboard Coast Guard cutter Mohawk off Key West, Florida, in May ]999.

COSTS: US$8 million to US$10 million, depending on configuration.

DESIGN FEATURES: Combines the most favourable aspects of helicopter and aeroplane performance in passenger-carrying role. T-tail configuration instead of endplate fin layout used by earlier tilt-rotor designs (XV-15 and V-22 Osprey): this raises horizontal tailplane above rotor wake to minimise fore and aft pitching moment at transition phase of flight. Size of wing determined by requirement for it to hold all fuel for CG and safety considerations. Composites cross-shafts keep both proprotors turning in event of engine failure. Manual screwjack facility exists whereby the proprotors can be tilted into helicopter mode if cross-shafts fail. Designed using three-dimensional CATIA digital computer design system. Airframe has design life of 20,000 flight hours.

Refer also to Bell Boeing V-22 description for explanation of tiltrotor concept and for its extension to four-proprotor configuration.

FLYING CONTROLS: BAB Systems triplex digital fly-by-wire flight control system, with Dowty Aerospace actuators. T tail with conventional elevators; no rudder. Two-segment trailing-edge flaperons.

STRUCTURE: Aluminium fuselage structure with composites skinning; composites wing. Production fuselages, including cockpit, cabin and systems installation, will be built by risk-sharing partner Fuji Heavy Industries of Japan, which may also establish a third production line if substantial orders are won from the Japanese government; cabin doors and fuselage tailcone supplied by Kawasaki; wing and nacelles by Bell at Fort Worth, with final assembly line at new Bell tiltrotor manufacturing facility in Amarillo, Texas and at Agusta facility in Italy. Fuselage in three major sections: nose, centre and tail, with fuselage skin incorporating graphite stringers with Japanese Toray composites material. Same used for wing and nacelles, with upper and lower wing surfaces produced as single pieces.

LANDING GEAR: Retractable tricycle type, with twin nosewheels and single wheel on each-main unit. Messier- Dowty overseeing design, development and manufacture of integrated landing gear system, including legs, wheels, tyres, brakes, brake control and landing gear control systems.

POWER PLANT: Two 1,447kW Pratt & Whitney Canada PT6C-G7A turboshaft engines, installed in tilting nacelles at wingtips. each driving a three-blade proprotor. Nacelle interface units by AMETEK Aerospace Systems. Rockwell Collins EICAS; modified oil system, with dual pumps, to generate sufficient oil pressure when operating in vertical mode; several planetary gears also removed to achieve direct drive 30,000 rpm output. Nacelle transition achieved in 20 seconds. Fuel in integral wing tanks; usable capacity 1,401 litres. Provision for auxiliary fuel tanks.

ACCOMMODATION: Crew of two, side by side on flight deck, with dual controls. Maximum of nine passengers in standard aircraft. Crew and passenger door on starboard side, forward of wing. Accommodation pressurised and air conditioned; pressurisation differential 0.38 bar. Transparencies by Sully Produits Speciaux of France.

SYSTEMS: Equipped for flight into known icing. Lucas Aerospace DC electrical power systems. Intertechnique brushless electric pumps and motor-operated shut-off valves.

AVIONICS: Rockwell Collins Pro Line 21 package as standard.

Comms: Dual VHF radios; Mode S transponder. Cockpit voice recorder included as standard. Radar: Optional Rockwell Collins WXR-800 solidstate weather radar.

Flight: Dual VOR/ILS, DMF, and ADF, with integrated control of sensors by dual Rockwell Collins RTU-4200 radio tuning units. Rockwell Collins ALT-4000 radar altimeter optional. GPS included as standard, along with TCAS and FDR.

Instrumentation: Three 250 x 200mm active matrix colour LCD adaptive flight displays, including two primary flight displays and one multifunction display. Standby instrument system by Goodrich Aerospace. Jane's All the World's Aircraft, 2004-2005

Bell Boeing revealed in 1996 that studies had been in progress for some time for the development of a nine-passenger, Tilt-Engine VTOL passenger transport. The system was announced as being in the 6300kg weight class and carried a designation of D-600.

In November of that same year, the companies officially announced the joint venture to design, develop, and market the system, which would be called the Bell Boeing 609. The companies had earlier conducted extensive surveys in the civilian and commercial markets and concluded that a significant requirement existed for such a system. In fact, officials from both companies indicated that the need could possibly justify a thousand aircraft in the next two decades.

The companies feel that there are a number of possible missions, including emergency medical operations, law and drug enforcement, transport to and from off-shore oil rigs, search and rescue operations, and corporate executive transport.

It was also reported that the 609 could well be just the first of a whole family of such vehicles. In fact, there is a projected 620 version which could carry up to 20 passengers.

The seriousness of both Boeing and Bell for the program was accentuated by the fact that major subcontractors were selected during 1996. The prototype was also displayed publicly at the 1997 Paris Air Show, where it generated large interest. Following that show, the 609 was then displayed for a number of potential European customers.

With its somewhat-normal appearance, when the engines are in the non-tilted position, the craft doesn't have the appearance of a Tilt-Engine vehicle. As such, it is perceived more as a standard twin-engine corporate jet instead of a revolutionary new aircraft development.

The 609 has also been proposed as an addition to the helicopter and fixed wing fleet of the U.S. Coast Guard. In fact, the 609 was evaluated in 1998 by the Coast Guard as a part of its "Deepwater" initiative, which would involve the upgrading of Coast Guard aircraft for the 21st century. An initial assessment of 60-90 609s might be required for this mission if it were to be selected.

Planning for the actual production of the 609 was well underway by 1997. Officials explained that the fuselage would be produced at Boeing's Vertol facility near Philadelphia, while the wing, as well as final assembly, would be accomplished at Bell's Fort Worth operation.

Plans during the late 1998 time period called for certification in both the United States and Europe during the first quarter of 2001, with deliveries planned to commence shortly thereafter. As of late 1998, there had been orders for some 60 planes. At that time, about one-third of the planes would support natural resource companies, another third to air-taxi companies, while the final third would go to corporate customers. This wide range of uses points to the flexibility of the Tilt-Wing model.

The 609 incorporates a unique advantage in that it will be able to land on heliports atop large buildings in metropolitan areas, a la a helicopter. But once in flight, and following the transition from vertical to horizontal flight, the 609 can assure the high-speed characteristics of a corporate jet, along with the sleek looks of that type of machine.

The model is projected to be in the $8-to-10 million dollar unit cost range. It should be noted that figure is considerably higher than a conventional helicopter, so the speed and pay-load advantages of this system must be evaluated by the prospective customer.

An extensive flight test program was planned with the construction of four test planes. The fourth vehicle would be used by the contractors as a demonstration vehicle. The goal of the flight test program was to firmly prove every aspect of the concept, looking at every part of the vehicle from a performance and cost point-of-view.

The projected capabilities of the 609 are impressive, with a cruise speed of 510km/h, a service ceiling of 7625m, and a maximum range of 1200km. All of those capabilities greatly exceed those of existing helicopters, making the 609 a very attractive alternative.

It has been noted that the 609 could cover about five times the area covered by a helicopter in a search and rescue operation, along with transit times to and from a destination being reduced as great as fifty percent as compared to pure rotary-wing aircraft.

Compared to the V-22 military system, the 609 is a very small system, but the concept is basically the same with the same Tilt-Rotor mechanism.

The 609 design incorporates a T-tail, which raises the horizontal member above the rotor wake and reduces their pitching moments during the transition portion of the flight. The relatively small-span wing size was determined by the need for it to hold all the fuel for center of gravity and safety considerations. The engines are cross-shafted, using composite materials, which will enable the craft to stay aloft in case of an engine failure. Also, in the case of cross-shaft failure, there is a screwjack arrangement which allows the rotors to be tilted into a vertical helicopter-style mode.

The flying controls are high-tech, with a Lear Astronics triplex digital fly-by-wire system. The T-tail has no rudder, but is equipped with conventional elevators and two-segment trailing edge flaperons.

Looking at the structure, composites again play heavily in the skinning of the wing and fuselage. The fuselage is constructed in three main sections, the nose, center section, and tail. The upper and lower wing surfaces were each produced as a single piece. In all, the 609 weighs in at a minimal 6300kg.

Due to its large use of composites, the production procedure for the 609 will be modified. Spools of carbon fiber material will be fed to computer-controlled machines. There, the material is coated with epoxy and then is laid on a mold in long crisscrossing bands.

The procedure came about from the V-22 experience when Boeing found out that it could use such skin panels to replace numerous smaller panels, thus eliminating the need for hundreds of fasteners.

Landing the 609 is accomplished on a retractable tricycle landing gear, with twin nose wheels and a single wheel on each rear fuselage unit.

Power is provided by a pair of 1850hp Pratt & Whitney Canada PT6C turboshaft engines, each of which is installed in the wingtip tilting nacelle. Each engine drives a large three bladed propeller. The unique use of the engines required some significant modifications, including a modified oiling system with dual pumps in order to provide sufficient oil pressure when operating in the straight-up mode.

The 609 carries a crew of two, located side-by-side on the flight deck. The cockpit features three large electronic displays, built by Rockwell Collins. The standard version is also capable of carrying a passenger load in air conditioned and pressurized comfort. S.Markman & B.Holder "Straight Up: A History of Vertical Flight", 2000

| Technical data for Bell 609

Crew: 2,

passengers: 6-9,

engine: 2 x Pratt & Whitney PT6C-67A rated at 1360kW,

max speed: 510km/h,

range: 1390km

|

Warning: mysqli_connect(): php_network_getaddresses: getaddrinfo for mysql5.zone.ee failed: Name or service not known in /data03/virt15346/domeenid/www.aviastar.org/htdocs/helicopters_eng/bell_609.php on line 152

Fatal error: Uncaught mysqli_sql_exception: php_network_getaddresses: getaddrinfo for mysql5.zone.ee failed: Name or service not known in /data03/virt15346/domeenid/www.aviastar.org/htdocs/helicopters_eng/bell_609.php:152

Stack trace:

#0 /data03/virt15346/domeenid/www.aviastar.org/htdocs/helicopters_eng/bell_609.php(152): mysqli_connect('mysql5.zone.ee', 'd14657sa18989', Object(SensitiveParameterValue))

#1 {main}

thrown in /data03/virt15346/domeenid/www.aviastar.org/htdocs/helicopters_eng/bell_609.php on line 152

|