Aircraft Profile #108. de Havilland Comet |

|

|

On 11th March 1943, the Government announced its intention to direct some efforts towards the design of civil transport aircraft, after reports from tours of the American industry by Sir Ralph Sorley and Sir Roy Fedden, warning of the amount of work being done on civil aircraft by the Americans. This led to the formation of the Brabazon Committee. In an attempt to offset the wartime lead that the Americans had established in the design and construction of transport aircraft, the Brabazon Committee recommended a number of design targets for the British Industry in May 1943. Type 4 was a jet propelled trans-Atlantic mail plane cruising at over 640km/h, capable of carrying a ton of payload and having a pressure cabin for the crew. In June 1943, official opinion was in favour of the project design, but nothing could go beyond this stage due to heavy commitments of building warplanes. However, the de Havilland Aircraft Company had made perhaps the earliest jet airliner study of a twin de Havilland Goblin engine powered Flamingo in mid 1941. These early designs were drawn round the de Havilland Goblin centrifugal jet engine developing some 1360kg static thrust. The later de Havilland Ghost was very similar in concept, but developed 2270kg static thrust. During the period January to June 1943, a short range civil design based on four Goblins was being considered. Later that year, a more detailed twenty passenger project was proposed having a Vampire layout with three Goblins in the rear of the nacelle. The design range was approximately 1100km. From November 1943 to April 1944 the design again changed to a canard layout with three DH Ghosts in the tail. On the 19th April 1944, the Brabazon Committee recommended the immediate go

In October 1944, a three DH Ghost twin boom layout with provision for six passengers and 900kg of mail was proposed by de Havillands to the Brabazon Committee. However, this project was becoming so specialised that an alternative proposal was made for a more conventional airliner. Studies were made with various fuselage designs in March 1945, seating twenty-four to thirty-six passengers. In October 1945, a tailless design was proposed having a 40° sweep wing, weighing 34,000kg and powered by four DH Ghosts. This idea was dropped in March 1946 as it was considered basically uneconomical, due to the limited effectiveness of the flight controls in this layout. However, much experience on this design was later obtained with the tailless D.H.108, three of which were built. By May 1946, a more conventional design with 40° wing sweep was proposed showing an Atlantic payload of 2270kg. Data provided from the D.H.108 showed the sweepback to be uneconomical due to the lower maximum lift coefficient and higher structural weight. If the sweepback was eliminated payload could be almost doubled. As a compromise, a more orthodox 20° sweepback wing aircraft was settled upon and so the final Comet shape was established during September 1946. By November 1946, a complete weight and performance statement was available with performance guarantees, all of which were met by the time the Comet entered service in

During 1946 and 1947, initial production orders were negotiated with B.O.A.C. for eight aircraft and with British South American Airways for six aircraft. After these two airlines merged, the contract was finalised with B.O.A.C. for fourteen Comets. The Ministry of Supply ordered the two prototypes to specification 22/46 as production aircraft. On 2nd April 1949, the first prototype was rolled out for engine runs. This aircraft was fitted with a large single-wheel undercarriage, which was later replaced by a four-wheel bogie type undercarriage. De Havilland Ghost engine flight development was undertaken in two specially modified Lancastrian aircraft, with the Ghost replacing the outboard Rolls Royce Merlins. The first flew on 24th July 1947, the pair of them flying 425 hours between them, thus contributing a great deal of experience towards the Comet's engine operation. The D.H.108 also helped with the development of the Comet's power controls, and in addition, a full size control system test rig was set up in the factory. This rig was in continuous operation for over three years. The whole aircraft structure was thoroughly tested starting with detail components and followed by the large assemblies. The wings were subjected to typical landing and flying loads of the worst type to be expected. Sections of the fuselage were installed in the decompression chamber at Hatfield to assimilate the conditions met at 21000m at a temperature of -70°C. The fuselage nose was the first section to be tested, by being given 2,000 pressure applications

At last the day came for the first flight of the new Jet Airliner on the evening of 27th July 1949, when John Cunningham took it into the air for thirty-one minutes with John Wilson and three other crew. From results of early flight testing the Comet appeared extremely competitive with the piston types then in use. The take-off weight was raised to 47600kg, carrying about thirty-six passengers for approximately 2400km at just under 800km/h. A great deal of attention was paid to the handling of the aircraft at both ends of the speed range, with generous flaps for the slow speeds and power controls to assist the pilot. The first public appearance was at Farnborough in September 1949, followed by the first overseas trip to Tripoli on 25th October, three months after the first flight. The total flying time there and back was only approximately six and a half hours. Many records were claimed by the Comet 1 including the London-Rome-London trip on 16th March 1950, each way taking just under two hours, and the London-Cairo trip taking five hours and seven minutes on 24th April 1950, the latter on the way to tropical trials at Khartoum. The second M.O.S. Comet G-ALZK made its first flight in INTO SERVICE The first certificate of airworthiness for Comet 1 G-ALYS was issued on 22nd January 1952, followed by the inauguration of the first Jet Airliner service by B.O.A.C. on 2nd May 1952 by Comet G-ALYP, when it left London Airport for Rome, Beirut, Khartoum, Entebbe, Livingstone and Johannesburg. The next Comet customer and the first from overseas, was Canadian Pacific Airlines, who announced an order for two Mk.lA's on 15th December 1949, the first being shown statically at Farnborough in 1952. Unfortunately, these never went into service, the second one, CF-CUN crashing at Karachi on its delivery flight to Sydney on 2nd March 1953. The first one was then resold to B.O.A.C. to replace G-ALYZ, which had crashed at Rome, the replacement becoming G-ANAV. The Series 1A Comet was an improved version of the Series 1, the fuel tankage being raised by 4500 litres to 31400 litres total, all the extra being in bag tanks in the wings. The all up weight was increased from 48000kg to 52000kg

On the 16th February 1952, the prototype Comet 2 G-ALYT made its first flight from Hatfield, having had its Ghost engines replaced by Rolls Royce Avons. This was conceived as a trans-Atlantic aircraft and B.O.A.C. ordered twelve of these fourty-four seaters after the tropical trials at Khartoum in May 1953. The Comet 2 had an all up weight of 54000kg and each of its Avons gave a thrust of 3300kg. The fuselage was 0.9m longer and the maximum still air range increased from 2850km to over 4000km. The payload went up by 770kg to 6100kg. This prototype of the Comet 2 was finally employed on de-icing tests with an Avon 524 in the starboard outer position, being sprayed with water from a special rig in front of the intake. This aircraft made its last short flight on 28th May 1959, when John Cunningham landed it on the grass airfield at Halton where it became 7610 M with No. 1 school of technical training. Although it will never fly again, this Comet is still doing a useful job teaching apprentices how to run the engines. THE ORDERS MULTIPLY At this stage, there were fourty-seven Comets on order or delivered, twenty-eight of these being the new Comet 2's. One of the new customers was British Commonwealth Pacific Airlines who ordered six Comet 2's for use between Australia and the West Coast of the United States of America. In the summer of 1952 Japan Airlines ordered two Comet 2's, followed

U.A.T. was the second operator to put the Comet into passenger service this being from Paris to Dakar on 27th December 1952 on a proving flight, followed by daily services from 19th February, 1953. Orders had really begun rolling in at this stage; Panair do Brasil ordered four Comet 2's with an option on the Series 3. Air France ordered three Comet 2's on 7th August 1953, their Comet lA's starting the service from Paris to Rome and Beirut on 26th August with F-BGNY. Shortly after this the B.O.A.C. order was amended to include only nine Series l's, the remaining five being completed as Comet 2's to bring the total of B.O.A.C. Series 2's to eleven. The two R.C.A.F. Cornet lA's were delivered to 412 Transport Squadron in the spring of 1953, becoming the first Comets in North America and the first military jet transports. In the first year of operation there had been two accidents in B.O.A.C. service, one with G-ALYZ at Rome on 26th October 1952 when it failed to get airborne and was damaged beyond repair, though nobody was injured. The second, and first major accident was exactly a year after the start of operations when G-ALYV broke up in a storm shortly after take-off from Calcutta on 2nd May 1952. After the two take-off accidents to CF-CUN and G-ALYZ a drooped leading edge was fitted to the wings of all Comets to improve take-off performance

By the end of 1953, all the Series l's and lA's had been delivered, the first production Comet 2, G-AMXA having flown at Hatfield on 27th August. To deal with the volume of orders, production lines for the Comet 2's were started at Chester and at Shorts of Belfast. With the closing of the year, U.A.T. and C.P.A. had ordered three Comet 2's, with Air France increasing their order to six Series 2's making a grand total of thirty-five on order. The orders for the longer range and larger Series 3 Comet was eleven including five for B.O.A.C. plus the Government owned prototype. The Comet was still the only jet transport in commercial service and working well. It was popular with passengers and operators and generally considered an outstanding success. TRAGEDY IN THE MEDITERRANEAN Then disaster struck. On Sunday 10th January 1954, the first production B.O.A.C. Comet 1 G-ALYP crashed shortly after take-off from Rome (Ciampino) and fell into the sea near Elba. The twenty-nine passengers and crew of six were all killed and B.O.A.C. grounded all their fleet immediately for careful inspection. After some sixty precautionary modifications were made to the fleet of Comets, covering all the suspected causes of the disaster, the Minister of Transport and Civil Aviation gave his permission for the services to be resumed on 23rd March. Shortly after this move, on 8th April, Comet 1 G-ALYY on charter to South African Airways again took off from Rome and after climbing to altitude came down in the sea

Pressure tests on G-ALYU were begun in June, with the fuselage immersed in a water tank. The normal operating pressure of 5812kg/m2 was applied to assimilate the normal aircraft operation, plus a proof pressure of 5kg every 1,000 pressurisations. This particular aircraft had in service already had 1,230 pressure flights and after a further 1,830 simulated flights, the cabin failed at the corner of a window, there being evidence of fatigue. As a comparison. Comet G-ALYP made 1,290 pressurised flights before crashing, and G-ALYY made only 900 before crashing. Meanwhile, during March and April, an enormous salvage operation had been taking place in the sea to a depth of 180m off Elba for the wreckage of G-ALYP. On examination of the wreckage, a failure was seen to have occurred on the top of the cabin starting at a crack in the corner of the cut-out housing the ADF ariel. This had rapidly increased causing an explosive decompression of the cabin and the break-up of the aircraft without any warning. From the evidence of the salvage engines, it was clear that these were in no way to blame for the cause of the crash. It was found by the Court of Inquiry that de Havillands had more than satisfied current British Civil Airworthiness Requirements for pressurised aircraft,

De Havillands had commenced in July 1953 to pressure test a representative section of the front cabin applying working pressure 18,000 times as well as approximately thirty higher pressurisations up to twice the working pressure. The results of these tests was a fatigue crack in the skin at the corner of a window, but this happened after such a number of pressurisations that the cabin was considered to be quite safe. It was pointed out at the inquiry that possibly this test specimen had lasted so long because the increase in pressurisation early on, to double the working pressure, might tend to increase the life of the specimen cabin. With the knowledge gained from the inquiry, de Havillands set about redesigning the Comet 3 to become the similarly shaped Comet 4. The earlier Mk.2's which had already been completed were extensively modified, as were the R.C.A.F. Mk. lA's, to have thicker fuselage skins, oval windows, spin dimpling instead of countersinking where possible, careful de-burring of all holes and cut-outs, and the jet pipes swept away from the fuselage to reduce buffet. The Comet 3 prototype had started its flight trials on 19th July 1954, while the second partly completed airframe was structurally tested, the wings separate from the fuselage. The fuselage was tested to failure during these tests when 105% of the design loads was achieved in bending, the patched up remains later being used as a customers' mock-up. Fortunately, the R.A.F. had a requirement for a jet transport aircraft and

Two other Comet 2's were modified, these being the Mk.2E's, additional modifications being to fit these with 4760kg static thrust Avon 524's in each of the outer engine bays in place of the normal 3330kg static thrust Avon 504's. Both of these, G-AMXD and G-AMXK, were used by B.O.A.C. during 1957 and 1958 on route-proving and engine handling training in preparation for the Avon 524 powered Series 4. When these trials were completed, G-AMXD became XN 453 and was used at Farnborough for long range radio aid development until it was relegated to fire fighting practice at Boscome Down. G-AMXK was fitted out as a development aircraft for the Smith's automatic landing equipment, starting with the Auto-flare for the Comet 4's, and finally the automatic landing system as fitted to the Belfast. THE COMET 4 The sole development Comet 3, G-ANLO, was without the new structure and could, therefore, not be fully pressurised, but despite this, it completed a large part of the C. of A. flying for the Series 4 including a round the world flight in December 1955. The Comet 3 was powered by Avon 502 engines, had large pod tanks on the leading edge and accommodation for a maximum of seventy-eight passengers. It was a similar shape to the Comet 4

In 1957, B.O.A.C. ordered nineteen Comet 4's as a standard aircraft for all their routes except the North Atlantic, although this was where it scored its major triumph on 4th October 1958 by inaugurating trans-Atlantic Jet services from London to New York. The second production airframe was installed in the test tank at Hatfield where it satisfactorily completed the equivalent of thirty years of airline life. On 30th September 1958, B.O.A.C. received their first two Comet 4's, G-APDB and G-APDC, four and a half years since the Comet 1's had been withdrawn from service. The last Comet 4 for B.O.A.C. was delivered on the llth January I960, by which time B.O.A.C. was flying them to all the Continents of the world, starting during 1959. In their first two years of operation, B.O.A.C. completed 43 million kilometres in a flying time of 68,500 hours carrying 327,000 passengers in their nineteen Comet 4's. Following the B.O.A.C. order was an order for three Comet 4's for Aerolineas Argentinas which was quickly made up to a total of six - their services commencing from Buenos Aires to Santiago on 16th April 1959, but an unfortunate

B.E.A. then went ahead and ordered the modified version with a 0.97m fuselage extension and shorter wing span, starting with six aircraft in April 1958 and finally totalling fourteen by continually taking up options. In conjunction with B.E.A., Olympic Airways ordered four Comet 4B's taking delivery during I960, two on the British register and two registered in Greece. Later, B.E.A.'s G-ARJL was added to the Olympic fleet. B.E.A. took delivery of their first aircraft on 9th November 1959, G-APMA having taken part in the Daily Mail London-Paris Air Race on 19th July. B.E.A.'s first scheduled services were operated on 1st April I960 with G-APMB from Tel Aviv to London, G-APMD in the reverse direction, G-APMF from London to Moscow and G-APMA from London to Nice. The final Mark of the Comet Series 4 was the export version designated the Mk.4C which had the high density fuselage of the Mk. 4B and the long range wing of

The last two airline customers were Sudan Airways, who had two Mk. 4Cs previously registered in Mexico for Mexicana, delivered at the end of 1962, and Kuwait Airways who also ordered two Mk. 4C's. Most of these Comets are still used on the London Airport Services, except the Mexicana aircraft which are rarely seen this side of the Atlantic. One of the most interesting of all the Comets was the one ordered for the personal transport of King Saud of Saudi Arabia. This aeroplane was luxuriously appointed, including a Royal Bedroom and had one of the most original colour schemes ever used on an aircraft. This aircraft came to an untimely end in the Alps on 20th March 1963. On 15th February 1962, the R.A.F. took delivery of the first of five Comet C. 4's for 216 Sqdn. Transport Command at Lyneham. These aircraft, XR 395

At the time of writing, the first airline to put their Comets on the second hand market is B.O.A.C, who have disposed of five to Malaysian Airways, two to Mexicana, two to Dan-Air and two to Ecuador with another on a six-month lease to East African Airways. The remaining six aircraft were lined up at London Airport awaiting a purchaser of these fine aircraft, the last B.O.A.C. scheduled service being from New Zealand on 24th November 1965, by G-APDM. All the other Comet operators are still going strong, finding the aircraft still has good operating economics and a great passenger appeal. The perseverance and determination of de Havillands to carry on in the face of disaster has born fruit with a total of seventy-five of the Comet Series 4 having been built. It is also remarkable that an aeroplane whose original design commenced in 1946 is still being developed into a useful maritime reconnaissance aircraft twenty years later. That of course, is another story. COMET 4 DESCRIBED The Comet is a moderately swept low wing structure of all metal stressed skin construction. The wings are made up of front and rear spars, with a false spar between, joined by closely spaced ribs. The wings are covered by machined pre-formed skins attached to the ribs by counter-sunk bolts. The stub wings are joined

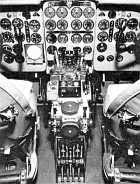

The twin wheeled nose under-carriage retracts rearwards, hinging from just behind the nose-located weather radar. The main undercarriage consists of a sideways retracting four-wheel bogie with the rear wheels trailing to absorb the first landing shock, the track being 8.59m. Maxaret anti-skid brakes are fitted with cooling fans and reverse thrust is fitted to the outboard engines. The cockpit layout is conventional for two pilots with full dual controls and engine and trim controls on a central pedestal. The third crew member in the cockpit is usually a flight engineer and there is provision for two more crew on the flight deck. The cabin of the Comet 4 can seat from sixty first class passengers four abreast, to eighty-one economy class seated five abreast. The longer fuselage of the Comet 4B and 4C can carry seventy-two first class, four abreast, going up to one hundred and one economy class, five abreast. Baggage holds are provided under the cabin floors with doors on the underside of the fuselage. The maximum width of the passengers cabin is 2.97m with a height of 1.98m. P.J.Birtles, 1966 |

All the World's Rotorcraft

|