|

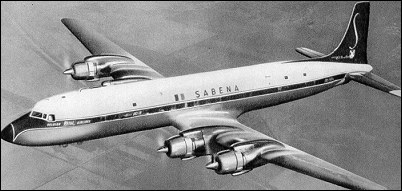

| Design and development of the Douglas DC-7 were prompted by American Airlines, which was seeking an aircraft superior in performance to the Lockheed Super Constellation being used by TWA. The Super 'Connie' benefitted from the use of new Wright Turbo-Compound engines, each of which had three exhaust-driven turbochargers giving some 20 per cent more output than the standard unit, and to meet the requirement of American Airlines it was decided to develop an improved version of the DC-6B using this new powerplant.

The initial DC-7 was a direct development of the DC-6B, with the fuselage lengthened by 1.02m to allow for the inclusion of an additional row of seats. Installation of the 2424kW R-3350 Turbo-Compound engines made possible an increase in gross weight of 6895kg, and required some strengthening of the landing gear structure. There were also some minor changes in detail, but externally the DC-7 appeared little different from the DC-6B.

A total of 105 DC-7s was built, and the 112 DC-7B aircraft which followed showed only minor changes. Most importantly, the engine nacelles were extended further aft to permit the installation of saddle tanks within the rear of the nacelles (which were made of the new metal titanium).

Not all operators opted for this additional fuel capacity, but those who did, such as Pan American which inaugurated non-stop London-New York services with the DC-7B on 13 June 1955, soon discovered that fuel capacity was marginal for North Atlantic services. In fact, with a full load and normal headwinds, DC-7Bs which were.used to operate the east-to-west service frequently had to divert for a refuelling stop. This was clearly unsatisfactory, and potentially dangerous, and Douglas set about the task of developing a version of the DC-7B with greater range.

The third version was designated DC-7C and had, therefore, increased span to provide for greater fuel capacity. This was achieved by inserting a new parallel-chord wing section between the fuselage and the inboard engine nacelles, which had the added advantage of improving the cabin environment by reducing engine noise. During the development of the DC-7C, Curtiss-Wright was able to offer a further increase in engine power and, as a result, the fuselage was lengthened by the insertion of a 1.02m plug to provide accommodation for up to 105 passengers.

Production of DC-7Cs totalled 120, and the alphanumeric suffix of this version became corrupted most appropriately to Seven Seas, for this aircraft wasabie to take the oceans in its stride without any problems. Not only were they used on North Atlantic and Pacific Ocean services, but they also made possible non-stop scheduled operations across the continental USA, and were used also by SAS to inaugurate a Europe-to-Far East route over the North Pole. An improved DC-7D was planned, to be powered by four 4273kW Rolls-Royce Tyne turboprop engines, but the emergence of the Boeing 707 and the Douglas Company's purpose-built DC-8 jetliner meant that this remained only as an unfulfilled project.

Because the turbo-compound engine increased operating costs, these fine air-liners disappeared quickly from the aviation scene when replaced by the first turboprop- and turbojet-powered airliners.

| CREW | 3-5 |

| PASSENGERS | 48-105 |

| ENGINE | 4 x Wright R-3350-18, 2500kW |

| WEIGHTS |

| Take-off weight | 64865 kg | 143004 lb |

| Empty weight | 35785 kg | 78893 lb |

| DIMENSIONS |

| Wingspan | 38.8 m | 127 ft 4 in |

| Length | 34.2 m | 112 ft 2 in |

| Height | 9.7 m | 32 ft 10 in |

| Wing area | 152.0 m2 | 1636.11 sq ft |

| PERFORMANCE |

| Max. speed | 650 km/h | 404 mph |

| Cruise speed | 560 km/h | 348 mph |

| Ceiling | 6850 m | 22450 ft |

| Range w/max.fuel | 9000 km | 5592 miles |

| Range w/max payload | 7400 km | 4598 miles |

| David, e-mail, 22.08.2023 00:18 1. The D.C.-7 is 4 Engine Plane is a Commercial Passenger Piston Plane too! The Cr using Speed Is 560 Km /h is 348 Miles Per Hour. Or 303 Knots too! Top Speed is 650 Km /h Or 404 Miles Per Hour. Or 351 Knots to Same speed too! Do You agree! Sir? Or Mam? reply | | Joyce Ottenstein DuPont, e-mail, 06.04.2015 03:01 My father worked for United Air Lines in Chicago, Cheyenne, Denver, and San Francisco. I remember flying as a small girl and passing out chicklette gum to the passengers. We flew from San Francisco to Hawaii and it took 8 hours as I remember. I went to work for United at age 18. reply | | Gary Dyer, e-mail, 10.02.2015 03:47 I am a retired United Airlines Pilot. May 4, 1964 to May 4, 2001. I flew the DC-7 in Denver at the training center. I don't recall which model it was. I think it was the "C". It was used as a trainer, having been retired from line service. It was referred to as the "white whale" as it was devoid of United markings and painted all white. I trained on it as a flight engineer first and then later as a co-pilot. training in those days was very long, three months training as a flight engineer and one month as a co-pilot. As a flight engineer we practically had to know how to build one. As memory serves me I flew the DC-7 as a freighter also. I remember the main landing gear served as "speed brakesin ". The PRT's could be observed glowing white hot at night. It was a dual rating the DC-6 and DC-7. The Curtis-Wright engines like to leak oil on the ramp. Most operators hung cans under the engines to catch the oil. reply | | Jack Beadle, e-mail, 10.01.2013 12:07 Flew the C as an airtanker and sprayer 1977 to 1988 loved every minute of it especially when Jim Dodds was wrenching on it. reply |

|

| | Timothy C. McClaughry, e-mail, 19.06.2012 00:16 As a young boy growing up near Stapleton International airport in Denver, Colorado, we played baseball in the vacant lots immediately under the East-West runway approach. The majority of the commercial airplanes flying overhead in the 1950s and early 1960s were the DC-6s and DC-7s. There is nothing about the sight and sound of the magnificent aircraft and their large radial engines that is not completly awe-inspiring. It is something that stays with you the rest of your life. God bless radial engines. reply | | Mike Diekman, e-mail, 30.08.2011 01:03 Hi I worked at Airlift !966 to 1970.ray titman and I worked the Fairbanks C130's in the winter of 1969,Both of us did the downrange contracts from Patrick AFB,for Nasa and USAF.The 7C was a great Aircraft,as long as you didn't have Smith Rebuilts on it. The Airforce would only alow 1 Smith Rebuilt Eng's on any Aircraft at a time,for there contracts. reply | | tudou, 20.06.2011 05:40 This would have been a separate variant as the larger R.R. Tyne powered DC-7D was, also, not built. reply | | Paul Lucas, e-mail, 11.03.2011 13:33 My first airliner flight was from Miami to Indianapolis on an Eastern DC-7B in July of 1960. I was 11 years old.

Love the old radials! reply | | W.G. Dickerson Jr., e-mail, 17.01.2011 22:16 I am an A&P mechanic retired from Northwest Airlines. I worked for Capitol Airway and Airlift International back in the 1960s. That was on Connies and DC-7s. You have to love those aircraft to work on them. I worked on them and flew on them for about 10 years and loved every moment of it. reply | | W.G. Dickerson Jr., e-mail, 17.01.2011 22:16 I am an A&P mechanic retired from Northwest Airlines. I worked for Capitol Airway and Airlift International back in the 1960s. That was on Connies and DC-7s. You have to love those aircraft to work on them. I worked on them and flew on them for about 10 years and loved every moment of it. reply | | Bill Macdonald, e-mail, 20.10.2010 07:25 I did the Brake Testing recording at Palm Springs, CA in the summer of 1953. Bert Foulds was our Pilot. We completed the Brake Tests for FAA Certification in 2 weeks, instead of the 4 weeks taken on earlier models. I synchronized the timing of brake application to the start of tire skid and came up with an optimum time to apply brake pressure to get the most efficient braking. reply | | David Hartman, e-mail, 28.08.2010 02:38 The DC-7 /7A /7B /7C's all had the PRTs. I'd almost say for such a large aircraft it has to be one of the quietest ever made. Even on takeoff it sounds like a couple P-51's but without the exhaust bark, due to the PRT sound suppression results. Only DC-7C I've seen flying is N869TA in Miami back in 1988. reply | | Peter Horn, e-mail, 21.04.2010 23:00 Oby,

Well, it almost might have happened. As I recall, Mr. C.R. Smith, (A.A. C.E.O. during this period) wanted to convert up to 20 DC-7B's to Rolls Royce Tyne power. This was, of course, the standard size DC-7 /7B, rather than the larger DC-7C. This would have been a separate variant as the larger R.R. Tyne powered DC-7D was, also, not built. reply | | Jim Dodds, e-mail, 29.01.2010 04:51 Missed.I also work on some of the first ones at American Airlines around 1957 reply | |

| | Jim Dodds, e-mail, 29.01.2010 04:49 I was A & P mech on them when used to fight fires. reply | | Henry Best, e-mail, 08.11.2009 00:32 I was a second officer on the DC-7C with Riddle Airlines in 1961. The engines did have engine driven superchargers to cram air into the induction system as all big engines did. However it also had PRTs. A turbine spun by the exhaust that provided power directly to the crank shaft through a fluid coupling. reply | | Oby, e-mail, 29.08.2009 20:21 is there a way of outfitting and DC4 /6 /7 aircraft with turbo Props? such as the ones found on the BT-67 (Converted DC-3) if so please let me know. also, as i recall the Turbo-superchargers on teh DC-7C made the engines such that theyy out performed the Super Connnie by about 150 Horses per engine. reply | | Bill Hodges, e-mail, 26.05.2008 04:35 My first long flight,from Houston to NYC, was on an Eastern AL DC-7. I was 13 (1956) and loved every minute! reply | | Harry Moss, e-mail, 03.10.2007 16:41 I believe the engines on the DC7C were R3350EA4 models reply | | thawkins, e-mail, 23.09.2007 02:54 The "turbo-compound" engines are not "turbo-charged". The power provided by the turbos is sent directly to the engine crankshaft via a fluid drive transmission. This device is called a "PRT" for power recovery turbine. reply |

|

Do you have any comments?

|

|

COMPANY

PROFILE

All the World's Rotorcraft

|

Hi Uncle Jack! It's your nephew, Jack Abrams, grandson of Michael Beadle, it's great to see you here, I'm following in your footsteps and am becoming a pilot and hopefully will be an air tanker one day

reply