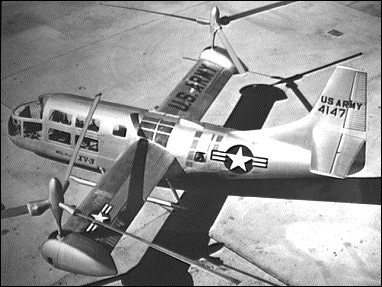

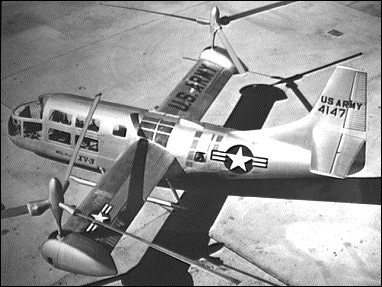

| Bell XV-3 1980 |  |

|

| Bell XV-3 1980 |  |

|

|

By the late 1940s the unique capabilities of helicopters became recognized and were being exploited for both military and civilian purposes. As their use expanded, limitations also rapidly became apparent. Most noted was their limited top speed, resulting from their inability to counteract the roll at higher speed that resulted from the rotor advancing into the airflow on one side, while retreating on the other. One attempt to counter this phenomenon was the compound helicopter that used small wings to pick up the flight loads as forward speed increased. This reduced the loading on the rotor, and thus the rolling tendency at higher speeds. An alternate solution was the Tilt Rotor. This concept used a more or less typical helicopter rotor to take off and land, then tilted the rotor forward to serve as a propeller for conventional forward flight. The Tilt Rotor, with its rotor facing straight into the airflow, had the potential to allow a much higher forward speed than would the compound helicopter. Bell had worked on the Tilt Rotor concept since the late 1940s. They came to believe that the idea not only was practicable, but also was well within the existing state-of-the-art. In August 1950, the Air Force and Army announced an official Tilt Rotor design competition. Bell's proposal for their Model 200 won the competition for the XV-3 (originally designated the XH-33), and Bell was awarded a contract in May 1951. The XV-3 was built and initially flight tested at Bell's Ft. Worth, Texas, facility. Two prototypes were built, carrying tail numbers 4147 and 4148. The basic configuration was a metal fuselage with the slender metal wing mounted mid fuselage. A large helicopter-like rotor was mounted on each wing tip. The rotor shafts were oriented in a vertical position for take-off, landing and hover like a helicopter, and moved to the horizontal position for forward flight like a conventional aircraft. A single Pratt & Whitney R-985-AN-1 Wasp Junior piston engine, producing 400hp for flight and 450hp for take-off, was located in the fuselage just behind the wing. Although a more powerful engine would have been desirable, the Wasp Junior was picked because of its proven reliability. A series of gearboxes and drive shafts transferred power to the rotors. Fuel was stored in a 380 litres tank located in the fuselage just under the wing. The fuselage length was 9.25m, the wing span was 9.53m, the height was 4.14m, and the wing area was 10.8m2. The maximum speed was predicted to be 252km/h. Three-bladed, fully articulated, 7.63m-diameter rotors were used initially. They were driven through a two speed transmission that could be shifted to a lower gear to allow the rotors to turn at a lower speed while the engine maintained a higher speed for greater cruise efficiency. The rotor tilt was controlled by an electric motor enclosed in a fairing at each wing tip. Each rotor could rotate through a 90-degree arc from vertical to horizontal in 10 to 15 seconds. The pilot could stop or reverse the rotor motion at any point. Steady, stable flight could be maintained with the rotors in any intermediate position. Although the XV-3 was intended as a research vehicle to evaluate the Tilt Rotor concept and to provide design and test data, military contracting rules at the time required that it also be designed and demonstrated with a military mission capability. Thus, the XV-3's military mission was observation, reconnaissance, and medical evacuation. To accomplish this mission, it had mounting points for two litters. For military missions, the maximum range was calculated to be 890km with a pilot, two passengers, and 30kg of cargo. For a 185km combat radius, it could carry the pilot, three passengers, and 100kg of cargo. During development, wind tunnel tests of a powered scale aerodynamic and dynamic model were run in the Wright Field 6m wind tunnel in June-November 1951 to determine stability and control characteristics, and performance capabilities in all modes of flight. Tests confirmed that good propulsive efficiencies for cruise could be obtained using helicopter rotors as propellers by reducing the rotational speed to about half of that used for hover. Only minor design changes were recommended as a result of these tests. What the wind tunnel tests did not look at was the impact of the large, slow turning rotors on the aeroelastic and longitudinal stability of the aircraft at cruise speeds. Aeroelastic effects, which are the coupling of the bending motions of various flexible components on the aircraft, plagued the XV-3 throughout its early life. The analytical methods to predict such phenomena had not yet been perfected, and the need for such testing was not recognized until it was encountered in actual flight. However, engineers knew about elastic modes, and rotor whirl mode tests were performed using the engine and drive system in hover mode in an outdoor test facility. These tests duplicated the aircraft drive system from the engine to the rotor as closely as possible from both a mechanical and structural standpoint. Some rotor mechanical instabilities were encountered and corrected, then a 100-hour endurance test was performed, The first XV-3 (serial number 4147) was constructed between January 1952 and December 1954. The aircraft rolled out on February 10, 1955. Following roll out, airframe and control system proof load tests, vibration surveys, and system functional tests were performed. Then, with the XV-3 mounted on a tie down stand, full conversions and operation in helicopter and airplane modes were tested. Ground runs included a rotor stability survey and ten hours of full power operation. These ground tests were completed by August. No major difficulties were noted, and rotor stability checks showed the aircraft to be free of any resonance tendencies. The first hover flight was made on August 11, 1955, by a Bell test pilot, but limited progress was made in flight testing during the next three years due to continuing problems with wing/pylon/rotor instabilities during flight. The first of these occurred after only one week and 1.2 hours of flight time, during an air taxi test. It resulted in a hard landing, and the XV-3 sustained rotor and airframe damage. While the damage was not extensive, the discovery of the instability raised major concerns. Repairs were made, and several modifications also were made which were felt would eliminate the elastic coupling problem. These included stiffening the rotor controls and adding external struts to make the wing more rigid. The trailing 25 percent of the wing was made to droop during hover to reduce disturbance to the rotor airflow during hover, and also to reduce stall speed to 85 knots, making transitions at a lower speed possible. 200 hours of ground runs and tie down tests were made to evaluate these modifications before clearing the XV-3 to fly again. The next hover flight finally occurred on March 24, 1956. Confident with the ground test and hover results, Bell finally began envelope expansion flights in June 1956 and performed a nacelle tilt of 5 degrees on July 11. By July 25, they reached 70 degrees tilt and 150km/h forward speed when another rotor instability was encountered. Flight testing resumed on September 26 after more modifications were made to the rotor system and ground run evaluations were completed. On October 25, during another test flight, 4147 encountered another very severe inflight rotor instability and crashed. The pilot was seriously injured, but survived. Bell took a serious look at the entire rotor system, and decided that the basic design and characteristics of the three-bladed articulating rotor system were unsatisfactory for the XV-3. Prior to resuming flight testing with the second prototype, 4148, Bell made numerous changes. They kept the R-985 engine, despite its limited power, because of its very good reliability record. The flush engine cooling air inlet was replaced with a scoop that spanned across the top of the fuselage, from one wing root to the other. As had been done with 4147, the rotor controls were stiffened and the wing was braced with external struts on the bottom. The #2 XV-3 was shipped to NASA's Ames Research Center, where it flew in their 12m x 24m wind tunnel in September and October 1957. Serious flutter problems with the original three blade rotors were confirmed, and Bell decided to replace them with two-bladed, semi-rigid type rotors of 7.3m diameter, mounted on shorter masts. The semi-rigid, versus the fully articulated design, in itself further increased rigidity, which would decrease the possibility of aeroelastic coupling. While in the wind tunnel, pilots were able to practice conversion procedures and gear changes. Further changes to the two bladed rotor/pylon design were still required to eliminate pylon oscillations, but these changes were tested while still in the tunnel, and again appeared to eliminate the problem in all conditions that were tested. The pilots found conversion to be quite easy, but engine gearbox shifting proved to be difficult, requiring considerable manipulation of the pitch controller and throttle throughout the twenty second process. Flight testing of 4148 began at Bell on January 21, 1958. Conversions to 30 degree pylon angle and speeds up to 205km/h were accomplished by April 1, 1958. Pilots also demonstrated autorotation to a landing following a simulated engine failure. Helicopter characteristics were rated as good, especially in high speed forward flight, and vibration levels were lower than expected. By May 6, another rotor oscillation was encountered in flight at a 40 degree pylon angle, and the aircraft again was grounded. Bell, the Army, and NACA decided that another series of wind tunnel tests was in order. Unfortunately, the 12m x 24m tunnel at Ames Research Center was heavily scheduled through the summer, and the XV-3 sat grounded until being shipped to Ames in September. During this time, Bell conducted analog computer simulations to further analyze the instability problem and recommend configuration changes prior to beginning the wind tunnel tests. During October 1958, the XV-3 finally went into the 12m x 24m foot wind tunnel at NASA Ames, and more refinements resulted. Changes included increasing the control system stiffness to three times greater than original, adding counterweights in to the rotor collective control mechanism, and increasing the blade sweep angle. Flying resumed on December 11. On December 17, the XV-3 achieved 30 degrees tilt, and on December 18 achieved 70 degrees tilt. After making a few minor rigging corrections, a second flight was made and a full conversion to 90 degrees finally was achieved. The conversion was made in steps, starting at 167km/h in full helicopter mode and finishing at 213km/h in full airplane mode. A second full conversion was made the next day. This was three years after the date projected for full transition at the time of the XV-3's roll out. Over the next ten weeks, final aerodynamic and control system refinements were made, including adding a large plywood ventral fin to improve the poor directional stability. With all the changes that were made to the rotors and pylons, Bell tried something new to see if the wing really was contributing to the instability. The strut attachments were modified with locking devices that allowed the XV-3 to fly with the supporting struts either locked in place to maintain wing rigidity or loose to provide no support to the wing. They were hydraulically actuated, and the pilot could switch between the two settings in flight. Bell assumed that if the instability resumed with the struts unlocked, then the wing indeed did contribute to the problem. The new device was tested on January 16, 1 959, at rotor angles up to 85 degrees from vertical with no instability problems. On the January 22, the struts were removed and the XV-3 flew up to 220km/h with the rotors 50 degrees from vertical, again with no instability noted. A wheeled landing gear was added to the landing skids, and short take-offs were made on April 13, 1959, using less than 60m of runway, and using only two thirds power. Optimum rotor tilt angle was found to be ten degrees forward of vertical. The first in-flight gear change was made on April 14, 1959, and a forward speed of 220km/h was achieved at a much lower engine speed with an accompanying lower vibration level. The gear change took about ten seconds to accomplish. The process was very similar to shifting a manual transmission in a car, requiring manipulation of the aircraft's collective control, throttle, and clutch. By April 24, 1959, the XV-3 finally was ready for formal evaluation by the military. It was shipped to Edwards AFB for a two month flight evaluation that began on May 14, 1959. The joint Air Force and Army evaluation consisted of 38 flights and a total of 29.6 hours. Forty conversions were made, as were twenty gear shifts to lower the rotor speed while in airplane mode. Also demonstrated were power-off conversions from airplane mode to helicopter mode followed by autorotation to a safe landing. Flights up to 3660m were performed. Air Force and Army evaluators concluded that conversions could be performed easily at all airspeed and fuselage attitudes that were tested. They considered the concept to be operationally practical because of low down wash velocity and temperature, low vibration, reasonable noise levels, and excellent reliability. The XV-3 demonstrated good behavior during stalls, good rolling take-off performance, and good basic controllability without electronic or mechanical stability augmentation. On the negative side, items related to the prop rotor concept included an erratic lateral darting tendency and roll oscillations during hovering in ground effect. A large increase in power was needed as hovering flight was approached. Weak longitudinal and lateral-directional stability was also observed at low speed in helicopter mode, as was excessive blade flapping during longitudinal and directional maneuvering in airplane mode. There was high parasite drag in all configurations at high speeds. And last, the XV-3 displayed a fore/aft surging motion, especially severe in rough air, attributed partly to the use of large, lightly loaded rotors as propellers. Other shortfalls were typical of an aircraft designed as a research vehicle. These included performance being significantly less than predicted and weight growth. The design empty weight was 1580kg and grew to 1895kg, this before the Air Force added 72kg of instrumentation. At a gross weight of 2165kg, only the test pilot and about 190 litres of fuel (half the fuel tank capacity) could be carried. This gave a maximum endurance of one hour. In airplane mode in high gear and full power at 1220m of altitude, cruise speed was 189km/h true airspeed and wing stall was 185km/h. In low gear and full throttle, cruise increased to 213km/h and wing stall was reduced to 174km/h. The XV-3 was dived to 287km/h, which was the top speed due to limits of collective pitch. Short period longitudinal dynamic stability began to deteriorate at 222km/h, and was considered unacceptable at 240km/h. At the completion of Air Force testing, the XV-3 was shipped to NASA Ames where it remained on flight status through July 1962. By the time its flying career ended, the XV-3 had been flown 270 times by 11 pilots for a total of 125 hours. 110 full conversions were made by nine different pilots, six of whom performed the conversion on their first flight. Flight testing of the XV-3 clearly demonstrated that technology had not yet developed an understanding of the aeroelastic coupling that could occur between the wing and a large, slow-turning rotor located at the wing tips. It wasn't until the mid-1960s that engineers finally had a relatively complete understanding of the coupling problem, following the development of sophisticated analytical tools and more capable computers. Although the XV-3 demonstrated the feasibility of the Tilt Rotor concept, it was limited because of low power, an unsophisiticated flight control system, and relatively low twist, helicopter-like rotor blades. Several times Bell proposed replacing the powerplant with a Lycoming T-53 turboshaft engine of 600hp and making rotor and control modifications to eliminate the concept-related deficiencies identified during the Air Force evaluation, but the XV-3 never flew again. However, the XV-3's career was not over yet. Under a NASA contract, Bell continued studying the phenomena of aeroelastic coupling and ways to improve high speed flight. Two additional sets of wind tunnel tests using the XV-3 were performed. The first was done in July 1962, evaluating several changes aimed at increasing maximum speed, improving high-speed flight characteristics, and decreasing the rotor flapping that occurred during maneuvering. The tunnel was run at 240km/h before instabilities set in. Following modifications, the instabilities did not return until 295km/h. Using these results, Bell felt that they finally had a good understanding of the problem. In May 1965, the XV-3 returned to Bell, where further study, modifications, and ground runs were performed between July 1965 and March 1966. It then returned to Ames and again entered the 12m x 24m tunnel for the fourth, and last, time in May 1966. This time, the XV-3 was tested to 365km/h, the limit of the wind tunnel, without encountering any of the oscillations that had plagued the aircraft throughout its career. However, on May 20, while running at maximum tunnel speed and taking the last planned data point, both rotors tore loose following a wingtip fatigue failure, damaging the aircraft and permanently ending the XV-3's career. Following these events, the XV-3 was placed in storage for many years, spending time at Wright-Patterson AFB and Davis-Monthan AFB. Eventually the U.S. Army Aviation Museum at Fort Rucker, Alabama, acquired it for display. Although the XV-3 itself never achieved the promised high forward speeds that had been hoped for, it did prove that the rotor could be tilted, and thus free the helicopter from the limited performance inherent in the rotor being in the horizontal plane. The XV-3 demonstrated the basic practicality and technical advantages of the Tilt Rotor concept for use on a VTOL transport aircraft. It provided a firm data base with invaluable information for the eventual XV-15 and V-22 programs. S.Markman & B.Holder "Straight Up: A History of Vertical Flight", 2000

Experimental tilting-rotor convertiplane powered by one 450hp Pratt & Whitney R-985 piston engine. Made its first vertical flight on 23 August 1955 and went on to complete more than 250 flights, totalling more than 125 flying hours. It was the world's first tilting-rotor, fixed-wing aircraft to achieve 100% tilting of its rotors, and proved the design practical. M.Taylor "Jane's Encyclopedia of Aviation", 1989

This convertiplane was developed by Bell in collaboration with the American armed forces. It was the first aircraft in the world to make the transition from vertical to horizontal flight by rotating its wings, which had two articulated, three-blade rotors, doubling up as propellers in cruising flight. Two prototypes were built for the development programme, the first of which flew as a helicopter in August 1955. The four-seat fuselage with a large window area had a radial engine at the center to drive the rotors, while the wing movements were accomplished by electric motors. The landing gear consisted of two helicopter-type skids. The development programme for the XV-3 was suspended in 1966. G.Apostolo "The Illustrated Encyclopedia of Helicopters", 1984

In mid-1951 the Army and Air Force jointly began funding the development of Bell Helicopter's Model 200 tilt-rotor vertical takeoff and landing (VTOL) research aircraft in the hope that the machine's innovative propulsion system would revolutionize military VTOL flight. It was hoped that the Bell machine's two wingtip-mounted tilting rotors would give the craft both the VTOL capability of a helicopter and the higher speed and increased manoeuvrability of a fixed-wing airplane. The first prototype (serial 54-147) was initially designated XH-33 in the helicopter category, though this was changed to XV-3 prior to the machine's maiden flight in August 1955. The craft had the fuselage and tail unit of a conventional airplane, with the pilot's position and four passenger seats in the forward section. The single 450hp radial engine was mounted almost exactly amidships and drove the two fully-articulated, three-bladed wingtip rotors through a series of gear shafts. Both rotors were set in the vertical position for takeoff and landing, and were tilted fully forward by small nacelle-mounted auxiliary motors to produce horizontal flight. The first XV-3 prototype was damaged beyond economical repair in 1956 and its place in the evaluation programme was taken by a second, somewhat modified machine. This aircraft (serial 54-148) differed from the first example in having two-bladed rotors, a small ventral fin, and other detail changes. The second XV-3 was the first aircraft in history to fully tilt its rotors from the vertical to the horizontal while in flight, and the information obtained during its evaluation was of immense value during Bell's development of the later XV-15. The second XV-3 was jointly tested by the Army and USAF (in Army markings) until 1962, at which time it was turned over to NASA for further VTOL research. S.Harding "U.S.Army Aircraft since 1947", 1990 * * *

|